OVERVIEW

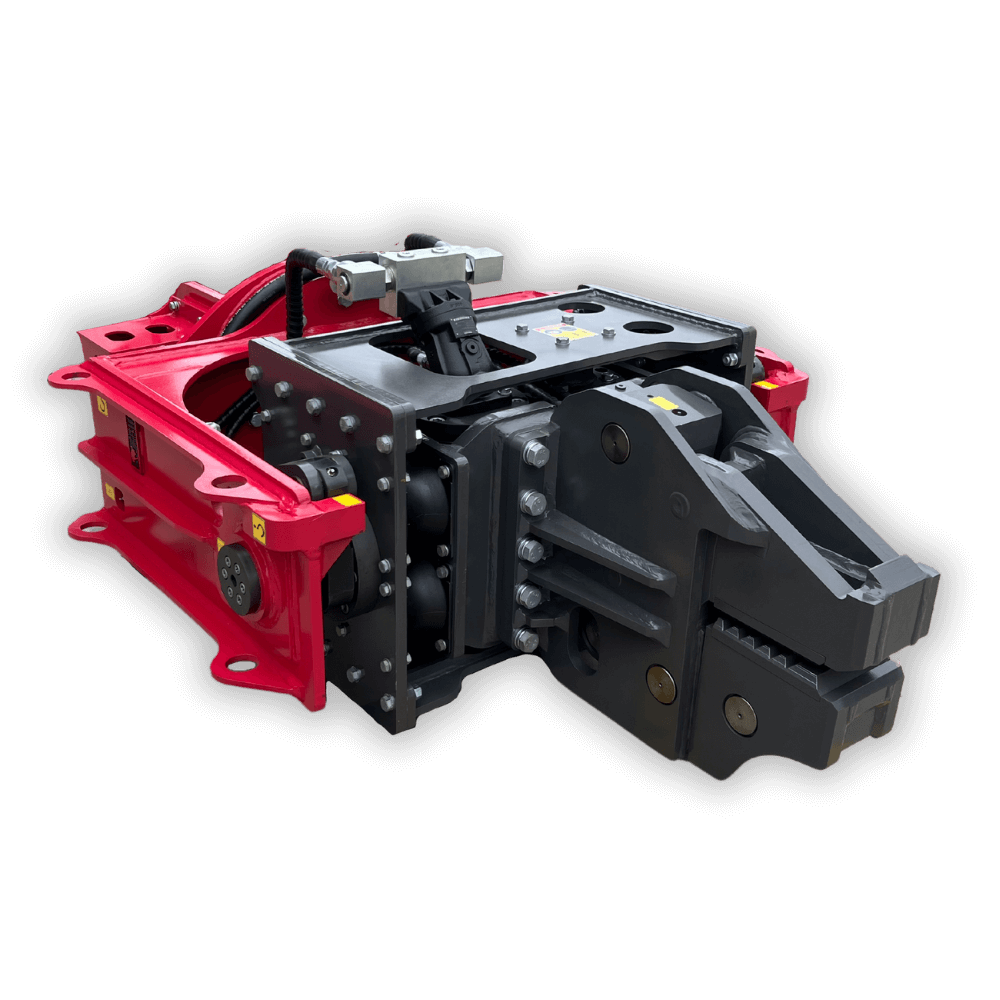

vibrating pile driver

available for 18t - 45t

The Vibrating Pile Driver is an innovative piece of equipment that offers a significant advantage in pile driving operations, greatly reducing the time required to complete the job.

The attachments' 90-degree tilting and rotating head enables it to pick up sheet piles in a horizontal position and easily position piles , minimizing the need for manual interference.

As a result, the operator can perform almost non-stop piling operations, significantly reducing the cycle time required to complete the work compared to basic types of pile drivers.

vibrating pile driver

available for 18t - 45t

The Vibrating Pile Driver is an innovative piece of equipment that offers a significant advantage in pile driving operations, greatly reducing the time required to complete the job.

The attachments' 90-degree tilting and rotating head enables it to pick up sheet piles in a horizontal position and easily position piles , minimizing the need for manual interference.

As a result, the operator can perform almost non-stop piling operations, significantly reducing the cycle time required to complete the work compared to basic types of pile drivers.

CHECK OUT THE VIBRATING PILE DRIVER IN ACTION!

FEATURES

FEATURES

90-Degree Tilting Function

360-degree Rotating Function

The 360-degree rotating function provides significant benefits in terms of efficiency, safety, and versatility. This feature enables the operator to position the machine and pile in the optimal direction, regardless of the excavation site's angle or position. By reducing the need for repositioning the machine or pile, this function can save time and effort, improving the machine's overall efficiency.

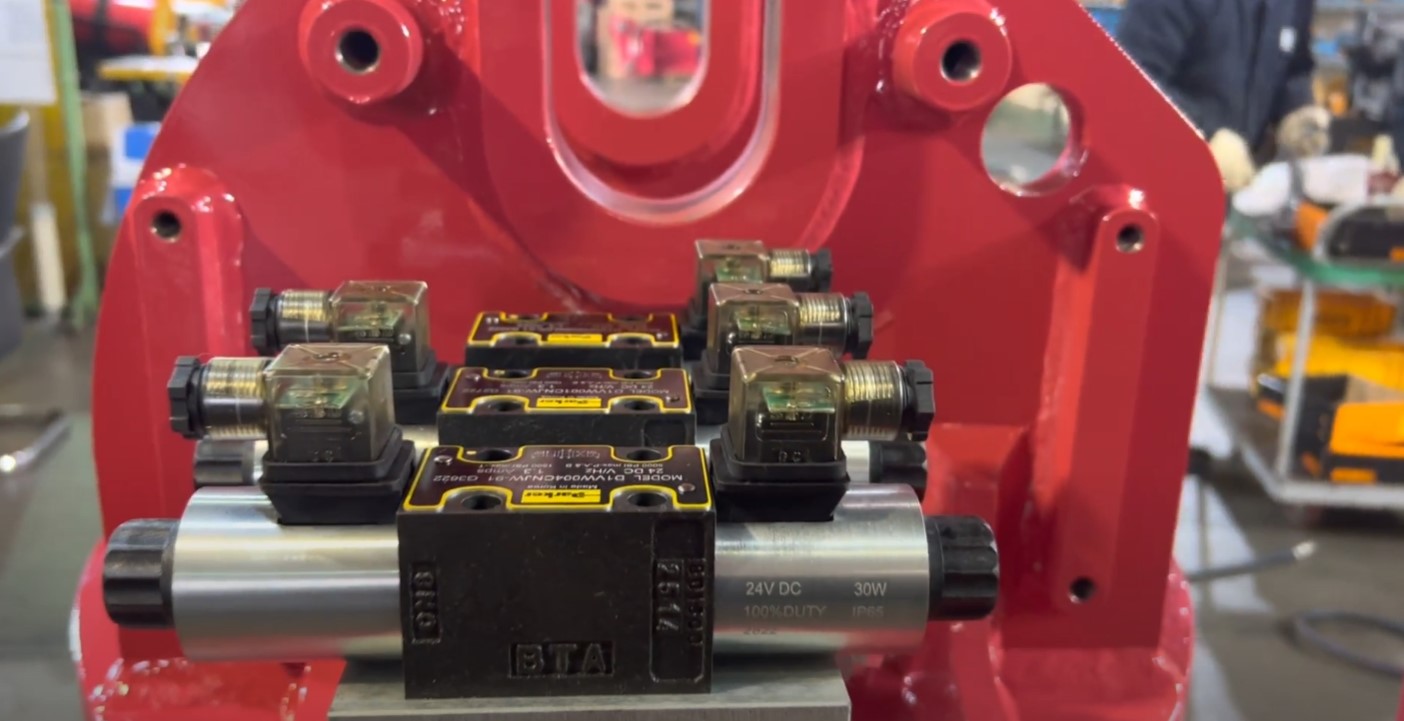

High Quality Electrical Harness

Heavy Duty Cylinder

Low Friction

Low friction is essential for the Vibrating Pile Driver as it helps minimize wear and tear, reduce energy consumption, and improve the overall efficiency of the machine. When driving piles, friction can cause a significant amount of energy loss, leading to reduced efficiency and productivity. By reducing the amount of friction, the machine can transmit more energy to the pile, driving it into the ground more effectively and efficiently.

Robust Construction

Manufactured with hardened pins and larger bushes decreases the overall torsional tension and provides maximum support, extending the Vibrating Pile Driver's life.

WARRANTY YOU CAN TRUST

GALLERY

GALLERY

.png)

.png)

ABOUT BULLSTERN

ABOUT BULLSTERN

and they have a proven track record of producing attachments that are built to last and perform consistently under the most demanding conditions.

By partnering with BULLSTERN, we are confident that we can provide our customers with world-class products, backed by a team of experts who are dedicated to delivering exceptional quality and service. Our Vibrating Pile Driver and Vibrating Ripper attachments are designed to meet the specific needs of our customers and are suitable for a wide range of applications, from construction and demolition to mining and excavation.

Our partnership with BULLSTERN is just one example of how we are working to achieve this goal, and we look forward to continuing to provide our customers with the best possible products and service in the years to come.

.png)

Mr. Yu

VICE PRESIDENT

We prioritize proven performance and quality through a meticulous process of local testing and customer feedback. This approach aids us in identifying and addressing any defects or usability issues that may have been overlooked during the design phase. This sets us apart from many Korean heavy equipment companies with export-oriented businesses, who often neglect the significance of field testing or launch their products into overseas markets without adequate testing.

BULLSTERN has an impressive company background. S & C Co. Ltd., a group specializing in the production of front actuators for construction equipment, has been a successful strategic partner with DOOSAN (previously DAEWOO) since 2000. Additionally, their technical know-how led to an OEM product contract with a leading Japanese brand in 2010, opening new prospects for their own brand attachment business named BULLSTERN.

BULLSTERN's journey, vision, and mission are defined by their motor of sincerity and challenge. With this approach, their mission is to become a global top-tier manufacturer for excavator-mounted attachments specialising in vibrating attachments.

Their top engineers are impressive, more than 30% of all employees are from DAEWOO, and most of them have worked for over 20 years. Mr. Yu, the vice president, is an expert on steel structures and is deeply involved in the design stage of all attachments developed by S & C Co., Ltd. This is why their attachments maintain high durability and long service life compared to others.

.png)

Mr. Yu

VICE PRESIDENT

We prioritize proven performance and quality through a meticulous process of local testing and customer feedback. This approach aids us in identifying and addressing any defects or usability issues that may have been overlooked during the design phase. This sets us apart from many Korean heavy equipment companies with export-oriented businesses, who often neglect the significance of field testing or launch their products into overseas markets without adequate testing.

Bullstern has an impressive company background. S & C Co. Ltd., a group specializing in the production of front actuators for construction equipment, has been a successful strategic partner with DOOSAN (previously DAEWOO) since 2000. Additionally, their technical know-how led to an OEM product contract with a leading Japanese brand in 2010, opening new prospects for their own brand attachment business named Bullstern.

Bullstern's journey, vision, and mission are defined by their motor of sincerity and challenge. With this approach, their mission is to become a global top-tier manufacturer for excavator-mounted attachments specialising in vibrating attachments.

Their top engineers are impressive, more than 30% of all employees are from DAEWOO, and most of them have worked for over 20 years. Mr. Yu, the vice president, is an expert on steel structures and is deeply involved in the design stage of all attachments developed by S & C Co., Ltd. This is why their attachments maintain high durability and long service life compared to others.

-png.png)

-png.png)

.jpg)

LOW CYCLE TIMES

![]()

The Vibrating Pile Driver is a revolutionary piece of equipment that has transformed the way pile driving operations are carried out.

This innovative attachment is designed to offer significant advantages in terms of efficiency, productivity, and safety compared to traditional piledrivers.

One of the most notable features of the Vibrating Pile Driver is its ability to minimize the need for manual interference during the pile-driving process.

The machine's 90-degree tilting and 360-degree rotating functions enable it to pick up sheet piles in a horizontal position, significantly reducing the requirement for manual intervention.

This feature allows the operator to perform almost non-stop piling operations, greatly reducing the cycle time required to complete the work compared to basic types of pile drivers.

By investing in innovative equipment, customers can expect to complete their pile-driving projects with greater ease, speed, and precision, ultimately resulting in significant cost savings.

%20(1)%20(1).png)

HIGH PERFORMANCE

%20(1)%20(1).png)

![]()

The Vibrating Pile Driver is a highly versatile piece of equipment that can handle a wide range of ground densities, making it a top choice for many construction projects.

With its advanced features, the Vibrating Pile Driver is capable of driving piles quickly and efficiently, even in challenging ground conditions.

Its 360-degree rotating and 90-degree tilting functions make it highly flexible, enabling the operator to position the machine and pile in the optimal direction, even in tight spaces.

As shown in the example on the graph, when driving an 8m long pile, depending on the ground density, would decide which size Vibrating Pile Driver attachment will be most efficient and effective for the job.

In this example, for loose ground types the smaller VPD1859 would be suitable in comparison to very dense ground where the VPD2384 would be more suitable.

![]()

Our Vibrating Ripper is engineered with low noise levels in mind, making it the ideal solution for urban areas where noise pollution is a concern. The attachment features an advanced hydraulic motor and vibration mechanism that work in unison to generate minimal noise during operation.

PRODUCTIVITY

![]()

The Vibrating Pile Driver is a versatile piece of equipment that offers significant advantages in pile driving operations. Its 360-degree rotating and 90-degree tilting functions allow the operator to position the machine and pile in the optimal direction, even in tight spaces, increasing the machine's flexibility.The Vibrating Pile Driver is a versatile piece of equipment that offers significant advantages in pile driving operations. Its 360-degree rotating and 90-degree tilting functions allow the operator to position the machine and pile in the optimal direction, even in tight spaces, increasing the machine's flexibility..The Vibrating Pile Driver is a versatile piece of equipment that offers significant advantages in pile driving operations. Its 360-degree rotating and 90-degree tilting functions allow the operator to position the machine and pile in the optimal direction, even in tight spaces, increasing the machine's flexibility

SPECIFICATIONS

SPECIFICATIONS

-

18-26t

-

25-35t

-

34-45t

-

18-26tNameVIBRATING PILE DRIVER (18-26t)FREQUENCY3800bpmECCENTRIC MOMENT3.6kgmCENTRIFUGAL FORCE580kNSETTING PRESSURE250bar (3625 psi)SLEWING / TILT360°/90°REQUIRED OIL FLOW180L/minMAX WIDTH57mmWEIGHT1859kgMore Info

-

25-35tNameVIBRATING PILE DRIVER (25-35t)FREQUENCY3200bpmECCENTRIC MOMENT6.2kgmCENTRIFUGAL FORCE700kNSETTING PRESSURE250bar (3625 psi)SLEWING / TILT360°/90°REQUIRED OIL FLOW210L/minMAX WIDTH57mmWEIGHT2189kgMore Info

-

34-45tNameVIBRATING PILE DRIVER (34-45t)FREQUENCY3100bpmECCENTRIC MOMENT7.6kgmCENTRIFUGAL FORCE820kNSETTING PRESSURE280bar (4061 psi)SLEWING / TILT360°/90°REQUIRED OIL FLOW260L/minMAX WIDTH57mmWEIGHT2384kgMore Info

DISCOVER OUR FULL RANGE IN OUR 2024 PERFORMANCE RANGE CATALOGUE

DOWNLOAD CATALOGUE

Fill out the form to get your 2024 Performance Range Catalogue straight into your inbox.

DISCOVER OUR FULL RANGE IN OUR 2024 PERFORMANCE RANGE CATALOGUE

DOWNLOAD CATALOGUE

%20(2).png)

.jpg)

.png)

-1.png)

.png)